Metal fabrication CAD drafting integrates digital design with physical production, enhancing efficiency and accuracy. 3D CAD models revolutionize sheet metal design, allowing precise visualization, simulation, and error reduction before manufacturing. This process involves conceptualization, digital modeling, detailed drafting, and meticulous cutting/bending/assembly techniques. Future trends include AI/ML integration for automation, optimized material use, and predictive performance analysis in smart factories under Industry 4.0.

In the realm of manufacturing, metal fabrication is a cornerstone process, transforming raw sheets into intricate components and assemblies. This article explores the symbiotic relationship between metal fabrication and Computer-Aided Design (CAD) drafting, specifically focusing on 3D CAD modeling for sheet metal. By delving into this technology’s benefits, design-to-production process, advanced techniques, and future trends, we uncover how it revolutionizes manufacturing efficiency, precision, and innovation in the metal fabrication industry.

Understanding Metal Fabrication and CAD Drafting

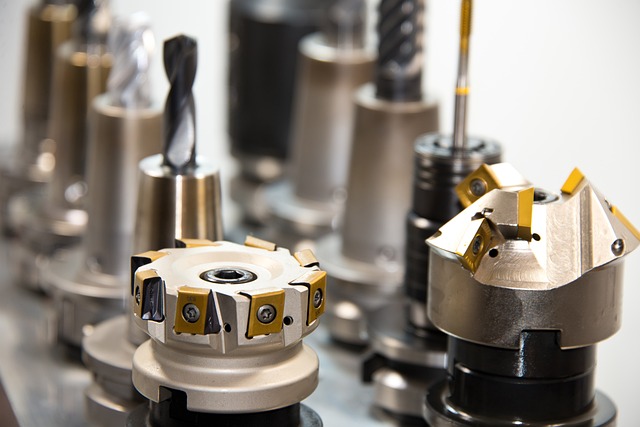

Metal fabrication and CAD drafting go hand in hand, revolutionizing the way sheet metal components are designed and produced. Understanding metal fabrication involves grasping the various techniques used to transform flat sheets into intricate three-dimensional forms—a process that requires precision and expertise. From cutting and bending to welding and finishing, each step demands meticulous planning and accurate measurements.

CAD drafting, on the other hand, is a digital process that enables designers to create detailed 2D or 3D models of sheet metal components. This technology allows for precise visualization, simulation, and optimization of designs before they are sent to the fabrication stage. By integrating CAD software into the design and drafting process, manufacturers can streamline workflows, reduce errors, and enhance overall productivity in metal fabrication.

Benefits of 3D CAD Modeling for Sheet Metal

3D CAD modeling brings numerous advantages to the realm of sheet metal components and assemblies. By transitioning from traditional 2D drawings, fabricators can unlock a new level of precision and efficiency in metal fabrication processes. This technology enables designers and engineers to create digital prototypes, allowing for detailed visualization and analysis of the final product before production begins. With 3D CAD, every bend, fold, and feature can be accurately defined, minimizing errors and rework.

Furthermore, integrating CAD drafting into sheet metal design facilitates better collaboration and communication. Digital models can be easily shared among team members, ensuring everyone works with the same up-to-date specifications. This streamlined approach not only saves time but also enhances overall product quality. By leveraging 3D CAD modeling, fabricators can optimize their workflows, reduce costs, and deliver complex metal assemblies with enhanced speed and accuracy.

The Process: From Design to Production

The process of creating sheet metal components and assemblies using 3D CAD modeling begins with design, moves through drafting, and culminates in production. First, engineers and designers conceptualize the desired shape and function of the metal parts, inputting these ideas into CAD software to create digital models. These models allow for detailed visualization and analysis, ensuring the component meets all necessary specifications before manufacturing even begins.

Once the design is finalized, precise drafting takes over. This step involves meticulously outlining every dimension, angle, and curve on the 3D model, transforming it into a set of 2D drawings ready for production. Metal fabrication specialists use these drawings as blueprints to cut, bend, and form the sheet metal into the exact shapes required, ultimately assembling them into complex, functional units.

Advanced Techniques and Future Trends

The evolution of 3D CAD modeling has brought about advanced techniques that are transforming the landscape of sheet metal fabrication. Beyond traditional 2D drafting, modern software now enables designers to create intricate 3D models, allowing for more realistic simulations and improved visualization during the development phase. This shift not only enhances design accuracy but also facilitates better communication between stakeholders, leading to faster prototyping and reduced time-to-market.

Looking ahead, future trends in metal fabrication CAD drafting promise even greater integration of artificial intelligence (AI) and machine learning (ML). These technologies are expected to automate repetitive tasks, optimize material usage, and predict structural performance, further streamlining the design process. As industry 4.0 gains traction, we can anticipate a more interconnected ecosystem where smart factories leverage advanced CAD systems for efficient production planning and execution, redefining the way sheet metal components and assemblies are created.

3D CAD modeling has transformed the landscape of sheet metal components and assemblies, offering numerous benefits over traditional 2D drafting methods. By leveraging advanced techniques in metal fabrication CAD drafting, manufacturers can streamline design processes, improve accuracy, and enhance productivity. The ability to visualize and manipulate three-dimensional models allows for better understanding and efficient communication among stakeholders. As technology evolves, continued exploration of these innovative practices will further revolutionize manufacturing, ensuring a vibrant future for the industry.