Precision sheet metal design services utilize advanced CAD software, laser cutting, and CNC machining to create detailed 2D/3D models for complex projects in automotive, aerospace, and construction. These technologies ensure accurate dimensions, materials, and finishes, enabling efficient manufacturing and high-quality outcomes while minimizing rework. Collaboration and detailed blueprints enhance production efficiency across diverse industries.

In the realm of fabrication, precision sheet metal detailing plays a pivotal role in achieving exacting outcomes. This article explores the intricate art of sheet metal design services, delving into why accuracy matters and how advanced technologies are transforming this field. We uncover the techniques that ensure flawless sheet metal detailing, highlighting their benefits across various industries. From meticulous measurements to innovative tools, discover how these practices enhance efficiency and quality in fabrication processes.

Understanding Sheet Metal Design Services

Understanding sheet metal design services is crucial for accurate fabrication. These services specialize in creating precise 2D and 3D models of metal components, allowing for detailed planning and execution of complex projects. By utilizing advanced CAD (Computer-Aided Design) software, professionals can transform engineering drawings into digital prototypes, enabling thorough analysis and simulation before production.

This process ensures that every detail is considered, from thickness and tolerances to material selection and finishing options. With accurate modeling, fabricators can employ efficient manufacturing techniques, such as laser cutting, pressing, and bending, resulting in high-quality, consistent outcomes. Sheet metal design services play a pivotal role in bringing intricate designs to life, catering to various industries like automotive, aerospace, and construction.

Importance of Precision in Fabrication

Precision is paramount in the world of fabrication, especially when it comes to intricate sheet metal design services. Every fold, bend, and cut must be executed with meticulous care to ensure the final product meets exacting standards. Inaccurate measurements or deviations during fabrication can lead to costly rework or even failure of the entire component. Therefore, investing in precision sheet metal detailing is not just a best practice but a necessity for achieving reliable and high-quality results.

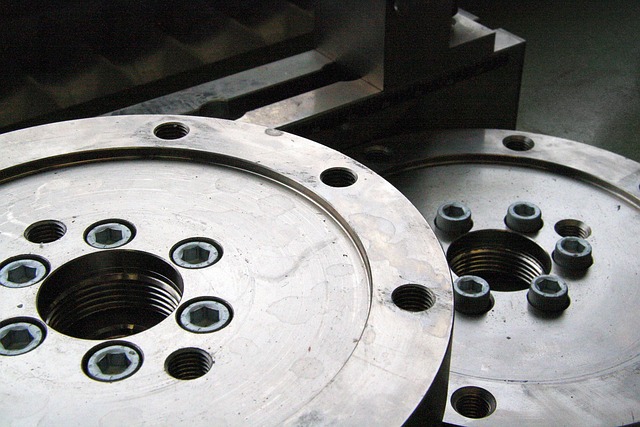

This level of precision allows manufacturers to produce complex geometric shapes with tight tolerances, ensuring each piece fits seamlessly into the larger assembly. Advanced technologies such as laser cutting and computer numerical control (CNC) machining play a pivotal role in accomplishing this level of detail and accuracy, making them indispensable tools for modern sheet metal design services.

Techniques for Accurate Sheet Metal Detailing

In the realm of precision fabrication, accurate sheet metal detailing is paramount. Skilled artisans employ a myriad of techniques to ensure every fold, bend, and cut is exact. Computer-aided design (CAD) software serves as a cornerstone, allowing for meticulous digital prototyping before physical production. This digital approach not only streamlines the design process but also enhances collaboration among team members, ensuring everyone works from the same detailed blueprint.

Beyond CAD, techniques such as laser cutting and CNC machining offer unparalleled precision. Laser cutters, for instance, can execute intricate patterns and cuts with minimal deviation, while CNC machines provide consistent, repeatable results, especially for complex shapes and contours. These advanced technologies are complemented by manual techniques like hand braiding and specialized tools for forming and expanding metal, ensuring a comprehensive suite of sheet metal design services capable of meeting the most demanding fabrication requirements.

Benefits and Applications of Advanced Technology

Advanced technology has transformed the landscape of sheet metal detailing, offering unprecedented benefits to fabricators and designers alike. One of the key advantages is the precision it brings; state-of-the-art machinery and software enable extremely accurate cuts, bends, and forms, ensuring every component meets strict tolerances. This level of precision is vital for complex projects, where even minor deviations can impact overall performance.

The applications of these technologies are vast within the sheet metal design services industry. From automotive manufacturing to aerospace engineering, advanced machinery allows for intricate designs and custom components. It streamlines production processes, reduces waste, and cuts down on rework, ultimately enhancing efficiency and productivity. With technology leading the way, fabricators can now offer more precise, complex, and innovative solutions, catering to diverse client needs in various industries.

Precision sheet metal detailing is a critical aspect of achieving accurate fabrication, ensuring that designs translate seamlessly into physical structures. By leveraging advanced technology and adopting meticulous techniques, manufacturers can unlock the full potential of sheet metal design services. This article has explored the importance of precision, outlined various detailing techniques, and highlighted the benefits of incorporating cutting-edge technology in this realm, ultimately fostering more efficient and precise fabrication processes.