Metal fabrication CAD drafting is a vital tool for designing robust sheet metal enclosures in industrial settings, ensuring structural integrity and functionality through precise 3D modeling, stress point simulation, heat transfer analysis, and optimized air flow. This technology streamlines production, facilitates customization, and enables early issue identification, resulting in durable housing solutions that meet unique industrial requirements.

Sheet metal enclosures and housings are essential components in various industrial applications, offering robust protection for sensitive equipment. This article delves into the critical aspects of designing these structures, from understanding specific application needs to leveraging advanced metal fabrication techniques and CAD drafting methodologies. We explore how precise engineering ensures optimal structural integrity and durability, making these enclosures indispensable in demanding industrial environments.

Understanding Sheet Metal Enclosure Design Requirements

Understanding the design requirements for sheet metal enclosures is paramount in industrial applications, where reliability and durability are paramount. These structures serve as protective casings for sensitive equipment, electrical components, and control systems, often facing harsh environments. Therefore, key considerations include material selection, structural integrity, weatherproofing, and ventilation to prevent overheating.

Metal fabrication CAD drafting plays a pivotal role here. It allows designers to create detailed 3D models, ensuring enclosures meet specific dimensions, clearances, and mounting requirements. With CAD, engineers can simulate stress points, analyze heat transfer, and optimize air flow efficiently. This meticulous approach not only enhances performance but also streamlines production, making it easier to customize designs for unique industrial needs.

Metal Fabrication Techniques for Industrial Housing

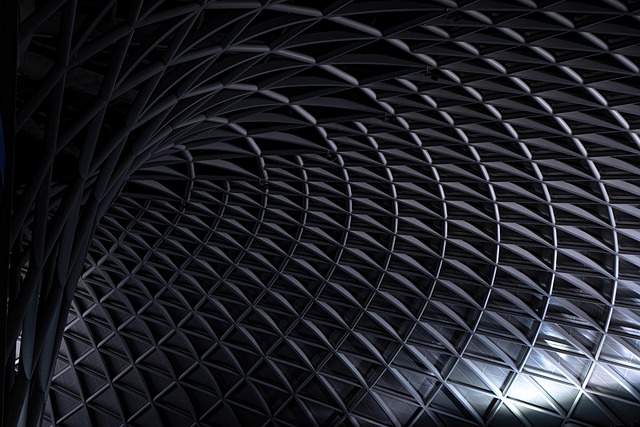

In the realm of industrial housing design, metal fabrication techniques play a pivotal role in creating sturdy and durable enclosures. This process involves utilizing advanced machinery and skilled craftsmanship to shape raw materials into precise, complex structures. With the integration of computer-aided design (CAD) drafting software, engineers can bring their creative visions to life with enhanced accuracy and efficiency.

Metal fabrication for industrial applications often begins with cutting and forming sheets of metal using laser or waterjet cutters. These tools enable precise cuts and intricate designs, ensuring structural integrity while allowing for customization. Once cut, the pieces are then bent, welded, and assembled, following detailed CAD blueprints. This meticulous approach guarantees that each housing component meets strict tolerances, resulting in robust enclosures capable of withstanding demanding industrial environments.

CAD Drafting: Creating Precise Enclosure Blueprints

In the realm of industrial applications, precise and detailed enclosure design is paramount for housing sensitive components and ensuring optimal performance. Metal fabrication CAD drafting emerges as a powerful tool in this process, allowing engineers and designers to create intricate 3D models with unparalleled accuracy. By utilizing computer-aided design software, professionals can meticulously outline every bend, cut, and assembly of the sheet metal enclosure, minimizing errors and maximizing efficiency during manufacturing.

This digital approach not only streamlines the design process but also facilitates quick modifications and iterations. With CAD drafting, designers can visualize the final product in a virtual environment, enabling them to identify potential issues early on and make informed adjustments. As a result, the end product is not just a functional housing solution but a testament to the marriage of advanced technology and meticulous engineering in metal fabrication.

Optimizing Structural Integrity and Durability in Design

In the realm of industrial applications, sheet metal enclosure and housing design plays a pivotal role in ensuring optimal performance and longevity. When designing these components, engineers must prioritize structural integrity and durability to withstand rigorous operational demands. One key approach is leveraging advanced metal fabrication techniques coupled with meticulous CAD drafting. By employing precision cutting, forming, and welding methods, every curve, angle, and joint can be meticulously crafted to enhance strength and stability.

CAD drafting software becomes an indispensable tool in this process, allowing for detailed 3D modeling and simulation. This enables designers to predict potential stress points, identify weak links, and implement reinforcement strategies proactively. Through iterative design cycles, the final product not only meets but exceeds industry standards, ensuring that the enclosure or housing can reliably shield its contents from environmental factors while withstanding internal pressures, vibrations, and other external challenges.

In the realm of industrial applications, a well-designed sheet metal enclosure is not just an aesthetic choice but a functional necessity. By understanding specific design requirements, employing advanced metal fabrication techniques, and leveraging CAD drafting for precise blueprints, manufacturers can create robust and durable housings. Optimizing structural integrity ensures these enclosures withstand harsh environments, while effective CAD integration allows for seamless customization and efficient production. This holistic approach to sheet metal enclosure design, combining metal fabrication and CAD drafting, is a game-changer in today’s industrial landscape, fostering innovation and ensuring long-lasting performance.