Laser-cutting sheet metal detailing transforms structural design with precision and versatility, enabling complex geometric patterns across industries. Prioritizing integrity involves selecting high-strength materials, meticulously designing joints, and strategically applying welds or fasteners. Balancing aesthetics and structure requires demanding precision and consistent material properties, with mild steel a popular choice. Advanced assembly methods and tailored fastening techniques ensure stability and appeal, leveraging laser-cutting technology for intricate designs to withstand environmental challenges.

In the realm of architecture and construction, sheet metal frameworks and support structures play a vital role in shaping modern structures. This article explores the intricate details behind precision metal shaping using advanced laser-cutting techniques. We delve into design considerations ensuring structural integrity, while examining material properties essential for robust frameworks. Additionally, we uncover assembly methods and fastening techniques that bring these metallic creations to life, revolutionizing building design with sheet metal detailing.

Laser-Cutting Techniques for Precision Metal Shaping

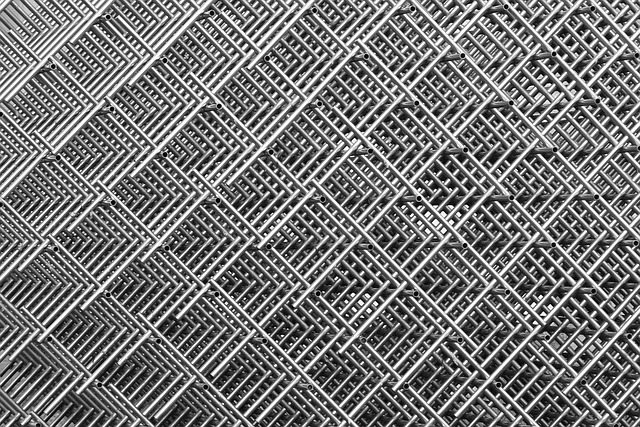

In the realm of sheet metal framework and support structure detailing, laser-cutting techniques have emerged as a game-changer. This advanced technology offers unparalleled precision in shaping metal, ensuring intricate designs are achieved with remarkable accuracy. By utilizing focused laser beams, engineers can cut, etch, and even perforate sheet metal with minimal waste and extreme detail. The process is not just efficient but also versatile, accommodating complex geometric patterns that were once challenging to produce.

Laser-cutting sheet metal detailing opens up a world of possibilities for architectural and industrial designs. From precise cutting to delicate engraving, lasers enable the creation of robust frameworks and support structures with consistent quality. This technology is particularly valuable in industries like construction, automotive, and aerospace, where precision and durability are paramount. With laser-cutting techniques, designers can translate their creative visions into reality, fostering innovative and functional metal structures.

Design Considerations for Structual Integrity

When designing a framework or support structure using laser-cutting sheet metal detailing, structural integrity must be a top priority. This involves careful consideration of factors like material selection, gauge thickness, and joint design. Choosing high-strength, corrosion-resistant materials ensures that the final product can withstand significant loads without compromising stability.

Proper joint configuration is paramount to maintaining structural integrity. Laser cutting allows for precise, clean cuts, enabling intricate joint designs that enhance overall strength. Strategically placed welds or mechanical fasteners further bolster the structure’s ability to resist forces acting upon it, be it weight distribution, wind load, or environmental stress.

Material Selection and Properties for Sheet Metal Frameworks

When selecting materials for sheet metal frameworks, engineers and designers must consider both aesthetic requirements and structural integrity. Laser-cutting sheet metal detailing, a popular method in modern fabrication, demands high precision and consistent material properties. Typically, mild steel is a preferred choice due to its strength-to-weight ratio, ease of laser cutting, and affordability.

The specific grade of mild steel can vary based on the project’s needs. For instance, higher carbon content steels are chosen for their increased hardness and wear resistance, while lower carbon variants offer better formability. Additionally, the addition of alloying elements like aluminium or zinc can enhance corrosion resistance, making the framework more suitable for outdoor applications or environments with high humidity levels.

Assembly Methods and Fastening Techniques in Metal Detailing

In the realm of sheet metal framework and support structures, assembly methods and fastening techniques are pivotal to ensuring structural integrity and aesthetic precision. Laser-cutting sheet metal detailing, for instance, offers unparalleled accuracy in creating intricate designs. This advanced technology enables precise cuts, allowing for seamless assembly where components interlock perfectly.

Fastening techniques, on the other hand, must complement the intricate nature of laser-cut details. Riveting, welding, and mechanical fasteners like bolts and screws are commonly employed. Each method has its advantages: riveting provides robust, permanent connections; welding offers invisible bonds that enhance structural strength; while mechanical fasteners offer quick assembly and disassembly, making them ideal for modular designs. Proper selection ensures the final product stands strong against various environmental stresses.

In conclusion, understanding the intricate dance of laser-cutting techniques, structural design considerations, material properties, and assembly methods is key to mastering sheet metal framework and support structure detailing. By leveraging these advanced manufacturing capabilities, professionals can create robust, precise, and aesthetically pleasing metal components that enhance a variety of applications. Optimizing material selection and employing innovative fastening techniques ensure durability and longevity, making laser-cutting sheet metal detailing a game-changer in modern fabrication.